Services

Plastic injection Molding From 50 to 250 tons

Custom Plastic Manufacturing

Mould Design & Manufactiring

Complete Assembly & Sub Assembly's

Mould Parts

Sharv Polyplast is customer centric leading plastic injection moulding company serving wide range of industries like Automobile, Electrical, Electronics, Gas Industry, Wind Energy, Solar, Fire Industry & Commercial Industry.

Do You Have Any Questions? Read Our FAQs Section and Feel Free to Ask

- Plastic Injection Mould Design And Development

- Plastic Parts Design And Development

- Conveyor Roller Plastic Parts.

- Packaging And Protective Plastic Parts.

- Automobile Plastic Parts.

- Instrument Enclosures Plastic Parts, Electronic Devices Plastic

Parts. - Canopies Plastic Parts.

Owing to our advanced manufacturing facilities, we have been

engaged in providing a quality-approved range of Turnkey Projects.

Some of the features of this activity are Product Conceptualization

as per Customer’s requirement and Idea, Product Design, Mould

Design & Development and Product Development and

manufacturing.

- Knowledge of Application CAD software’s and CAE software’s

- Know how reverse engine, Rapid Prototyping.

- Exposure to Product validation and testing methodology.

Our SetUp

MilaCron 150 Ton Nova Servo

- Climping Force 150 tons.

- Screw Cylinder injection Press 1731 Bar.

- Shot Weight 336 Gram

Toshiba 150 tons TS Servo

- Climping Force 150 tons.

- Screw Cylinder injection Press 2022 Bar.

- Shot Weight 402 Gram

Pinnacle VMC

- Tabel Size 1200X750 mm

- Load Capacity 3500kg

- Spindal Speed 7000-10000 RPM

- Controller MITSUBISHI M70

Hardford S-Plus

- Tabel Size 1000X550 mm

- Load Capacity 2,000kg

- Spindal Speed 10,000-15,000 RPM

- Controller MITSUBISHI M70

Moulding Facilities

150T Horizontal Injection Moulding Machine, 80T Horizontal Injection Moulding Machine

Ancilliary Equipments

Hot Air Dryers Tray Oven Mould Temperature Controller Cooling Tower Over Head Crane Crusher

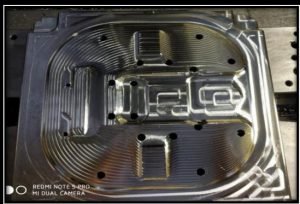

Mould Design & Development

Product facility includes mould design,mould flow analysis and mould manufacturing.