Plastic injection Mould

Customize Mold

We Manufacture Customization Moulds as per Customer Requirement

Doorstep Delivery

We Delivered Mold to your Doorstep.

Customer Support

We are 24/7 hr available for you.

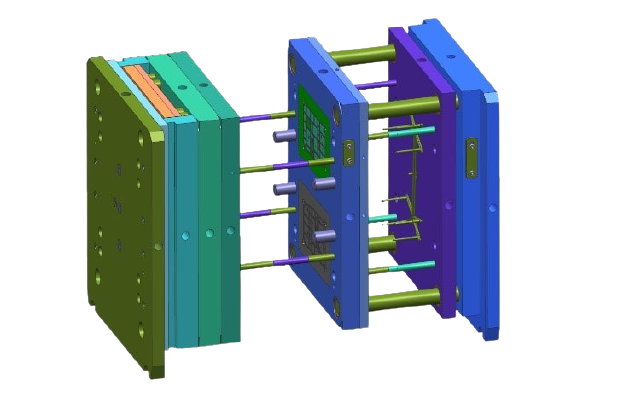

Three Plate Mold

We Manufacture Three Plate Mould System The three-plate mould differs from the more common two-plate design format in terms of utilizing more than one split or parting line. The tool construction is divided into three distinct plate build-ups which separate from each other on opening

Family Mold

A family mold has a single mold base but two or more different cavities, allowing for the production of two or more different parts. All the parts can either be produced simultaneously or shut-offs can be used to isolate production to selected cavities.

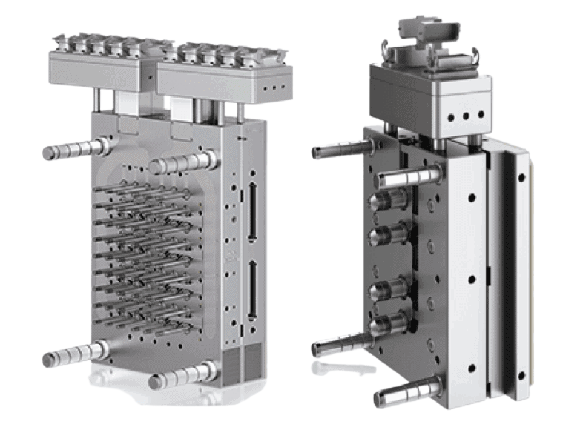

Manufacturing Best Hot Runner Molds

We are one of the most reliable companies in this domain and are into offering Best Preform Hot Runner it uses advanced mold design technology.

Hot Runner Injection Mold

Sharv Polyplast Manufacturing hot runner system Moulds, Which delivers liquid plastic to a number of mold cavities in order to create a plastic product. It is an injection molding assembly that uses a heated manifold to keep plastic in a molten state. This heated plastic travels from the molding machine nozzle through internal channels called runners and can be delivered directly into multiple cavities at the same time.

Sharv Polyplast Suggest, While the two systems differ in a number of ways, one of the key differences between the two systems is that hot runners are able to inject plastic directly into the part cavity. Thanks to this direct injection, the sprue and runners remain hot throughout the injection process so the only component removed each cycle is the part itself. Because of this, the mold can be cycled again very quickly. This feature makes for better-looking products, allowing for high detail and smooth surfaces due to a much smaller injection point

A hot runner makes it easier for a molding machine to inject plastic into a mould cavity. A hot runner increases the capability of a molding machine. It reduces the plastic flow length so a molder can save material by making thinner and lighter parts.